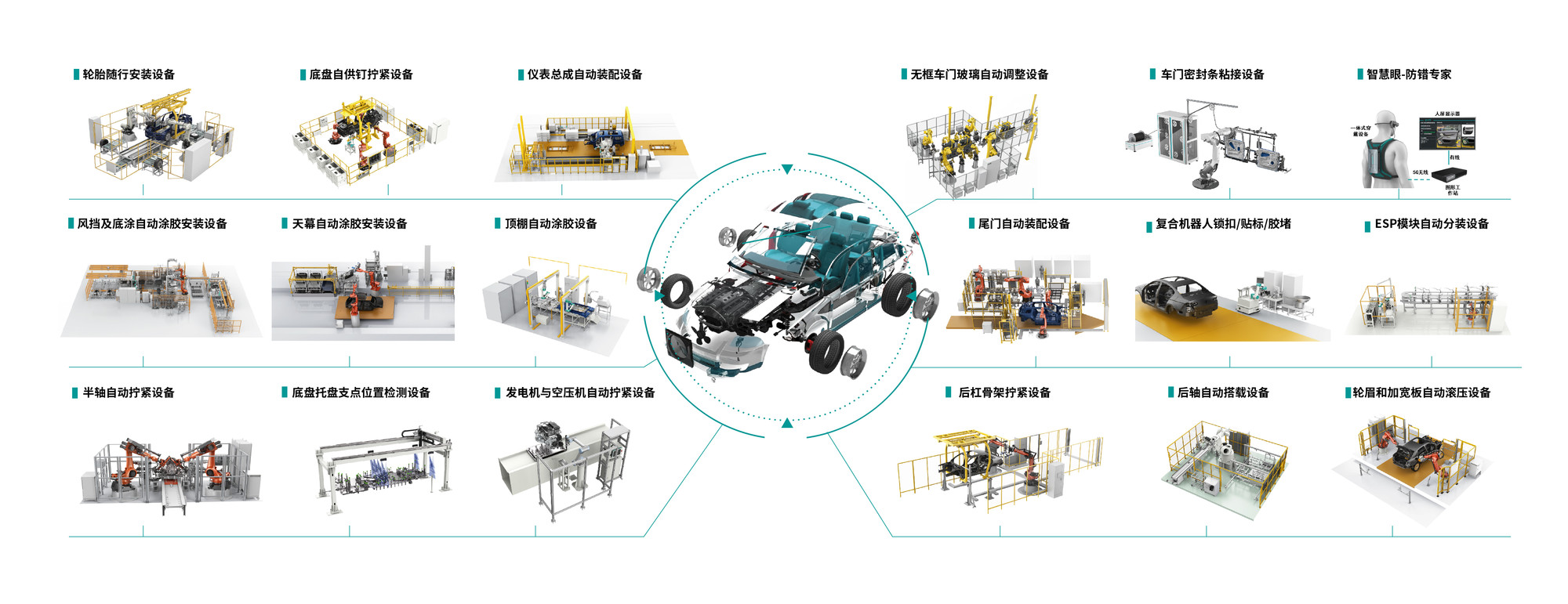

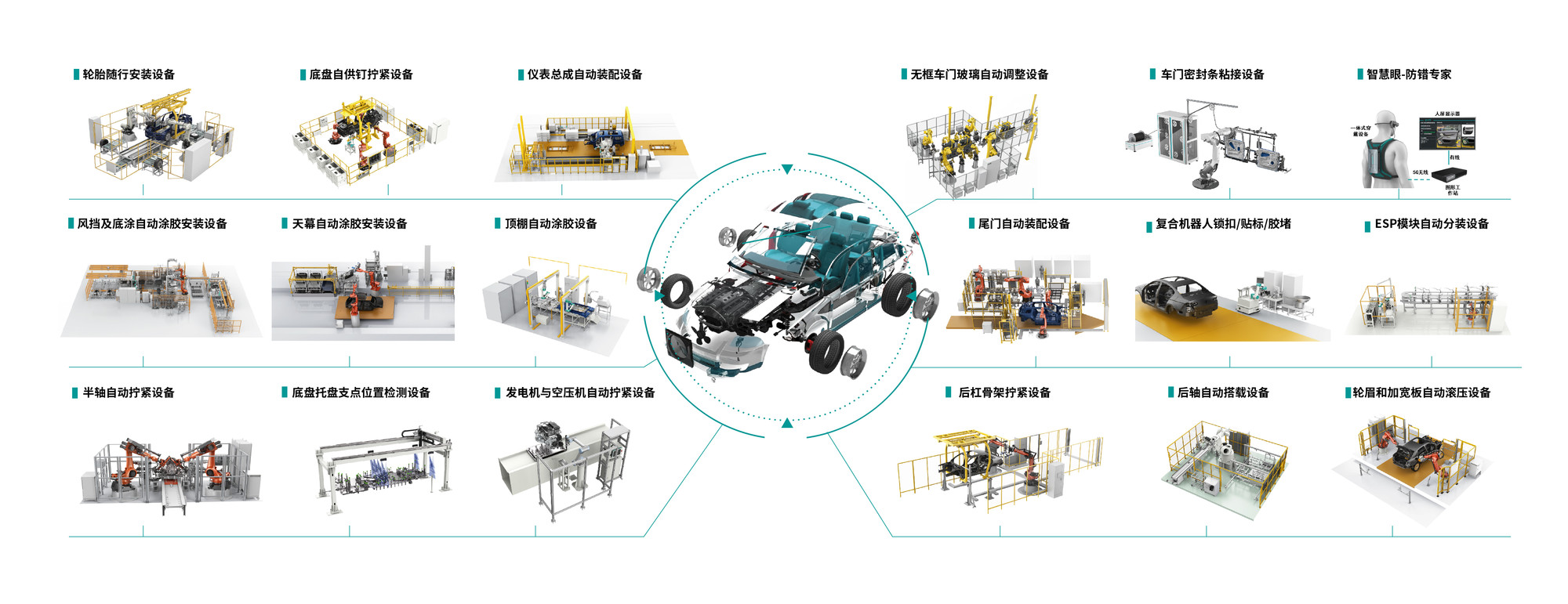

应用场景

Applications Scenarios

领先技术

Leading Technology

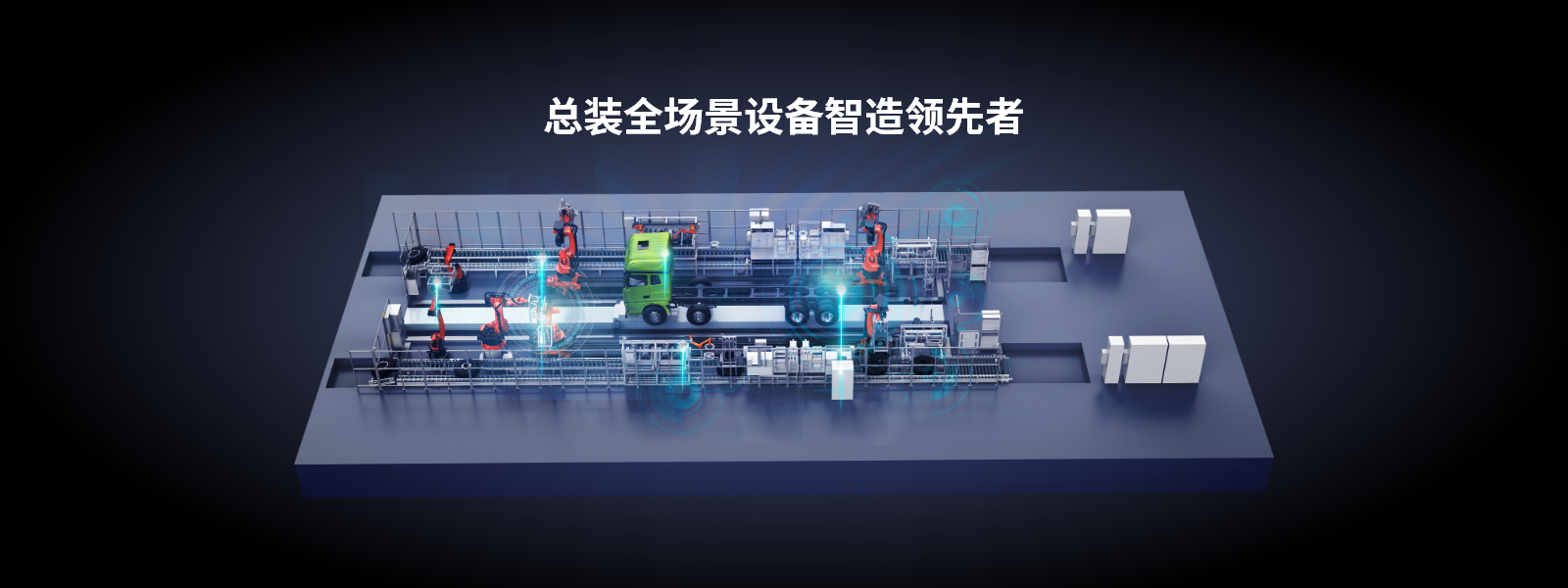

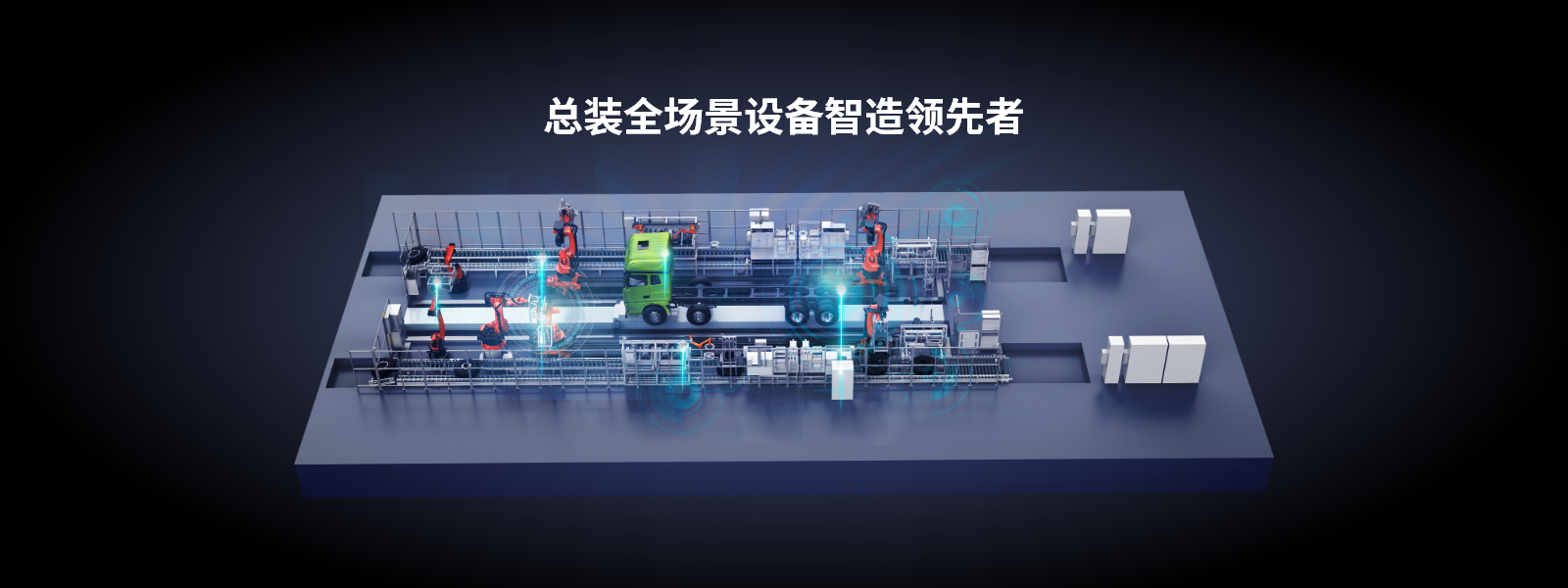

- 国内领先总装实验室,为客户提供经验证的可靠总装自动化解决方案

- 国内领先全自动随行轮胎装配系统,开创性地解决移动产线安装问题

- 全球领先卡车全自动轮胎装配工作站,引领重载商用车总装智能化

- 提供“智慧眼”AI质量防错识别分析系统,赋能人工作业环境,把深度学习技术引入智能装配领域

技术实力

Technical Strength

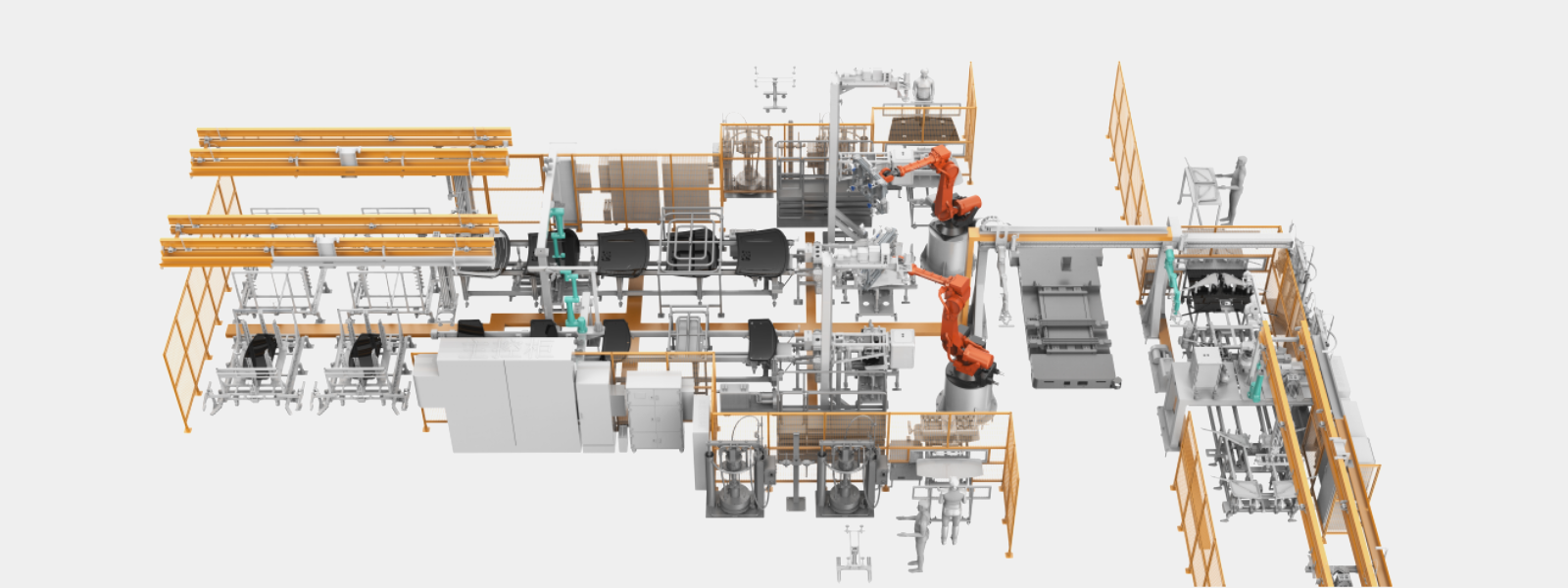

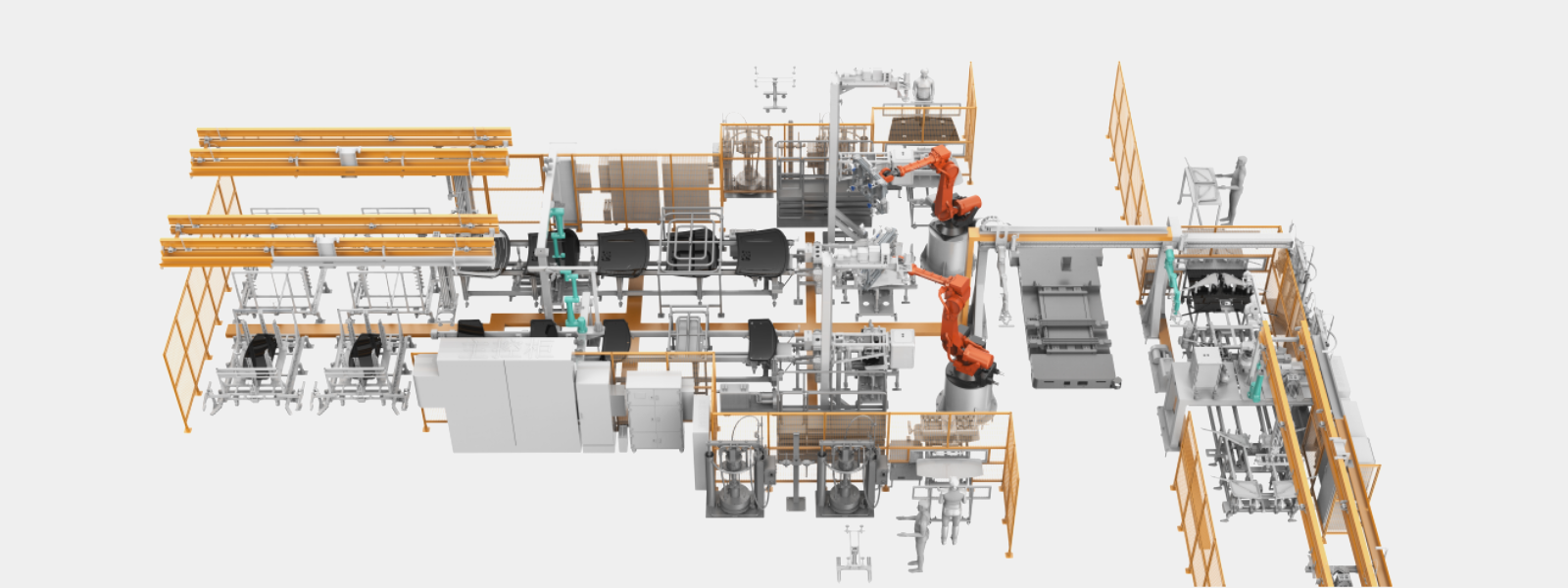

随行技术

包含适用于抱具随行技术、滑板随行技术、AGV 随行技术、适用于乘用车、商用车总装场景的轮胎安装、风挡安装、天幕安装、仪表安装等场景。

3D视觉引导技术

满足不同场景中抗环境光、高精度、高速度、小体积等多样化的需求,包括:光照影响控制、视觉引导精度、批量测试、图像处理速度、动态干扰抑制。

力控技术

通过力控技术成功实现了随机斜螺纹孔的螺栓拧紧。

智能检测技术

固智提供质量防错识别分析系统赋能人工作业环境,适用线束插接检测、实时装配检测、整车下线检测、底盘托盘检测支点位置检测、新能源电池领域等。

我们的客户

Our customers

联系我们

Contact us

固智机器人(上海)有限公司

固话:021-59556007

地址: 上海市嘉定区嘉松北路7455号

人事招聘

HR邮箱:hr@guchi-robotics.com

销售服务

销售电话: 021-59556007

销售邮件: sales@Guchi-Robotics.com

上海市嘉定区嘉松北路7455号

关于固智

联系我们

产品介绍

公司电话:021-59556007

HR邮箱:

hr@guchi-robotics.com

销售电话: 021-59556007

销售邮件:

sales@Guchi-Robotics.com

固智机器人(上海)有限公司官网

固智,名字来源于蒸汽火车前进时的声响,代表着持续不断的动力。

作为一个新兴的高科技企业,我们的远大愿望是实现释放全人类的

生产力。我们的产品不仅是机器人及其应用,我们更提供工程解决

方案,产品改进与创新,持续预测性维护,及备件共享仓储服务。

甚至,我们希望能把这些诀窍、专业知识传授出去,希望所有人都

能得益于这个新时代的来临。

固智所拥有的创新科技正在为建造一个更有效,更经济,更安全,

更环保的新型生产模式而竭尽全力。我们相信,在高科技的引领下

人类的未来定将更加美好。

https://user-assets.sxlcdn.com/images/40270/FkWC_SQjykVYZO0ZUuDhOvAJHOE_.JPG?imageMogr2/strip/auto-orient/thumbnail/1200x630>/interlace/1/format/jpeg